Le projet a été cofinancé par l'Union européenne à partir du Fonds européen de développement régional

18 mois de mise en œuvre = projet réalisé avec succès

Début de la mise en œuvre du projet : solutions TIC pour des produits plus compétitifs

L'entreprise ESCO-Fofonjka doo est le 05.02.2020. sur la base de l'adoption réussie de l'appel Améliorer la compétitivité et l'efficacité des PME grâce aux technologies de l'information et de la communication (TIC) - 2 a conclu un accord avec le ministère de l'Économie, de l'Entrepreneuriat et de l'Artisanat et l'Agence croate pour les petites entreprises, l'innovation et les investissements sur le projet cofinancement (subventions).

Nom du projet : Solutions TIC pour des produits plus compétitifs.

Les principales activités du projet :

- Achat de solutions commerciales TIC destinées à améliorer les processus commerciaux

- Mise en œuvre, adaptation et intégration de solutions commerciales avec le système TIC existant/nouveau

Objectifs et résultats attendus : L'objectif principal de ce projet est d'investir dans des solutions TIC pour accroître la compétitivité en augmentant l'efficacité des opérations d'entrepôt, des services de construction, des processus de comptabilité et d'approvisionnement, et ainsi contribuer à la réalisation des objectifs stratégiques de la stratégie industrielle. de la République de Croatie et les objectifs et documents de développement régionaux/locaux. En mettant en œuvre le projet, l'entreprise espère augmenter le nombre d'employés, augmenter le chiffre d'affaires, améliorer 4 processus commerciaux et utiliser des subventions.

Valeur totale du projet : 1 154 246,05 KN (TVA incluse)

Montant cofinancé par l'UE : 637 143,81 KN (hors TVA)

Période de mise en œuvre du projet : à partir du 15 janvier 2020. jusqu'au 15.07.2021.

Nouvelles :

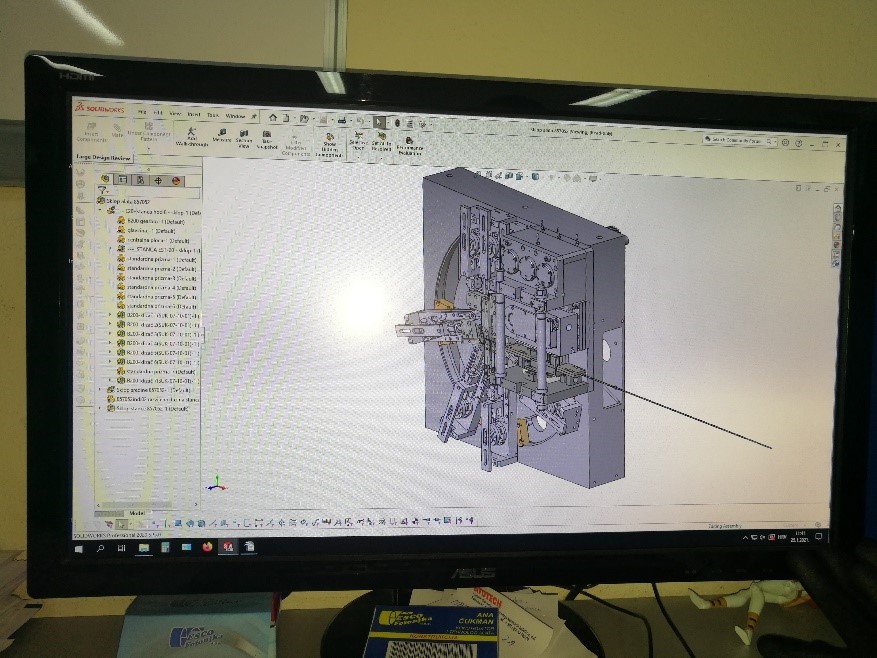

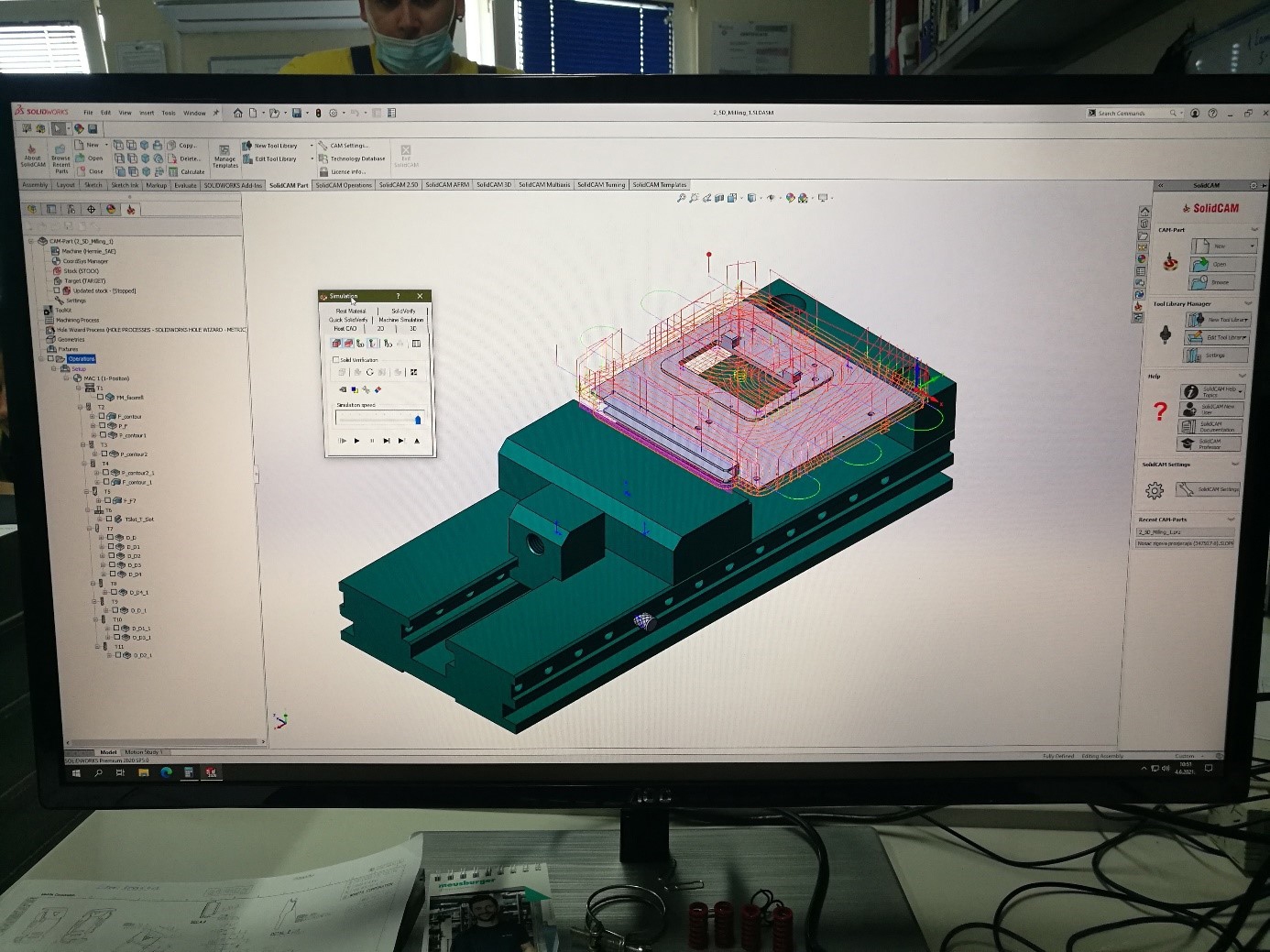

20.08.2020. - pendant les 6 mois de mise en œuvre du projet, nous avons réalisé les 10 activités prévues sur cette période de 6 mois. En plus des activités de visibilité du projet (publications sur supports numériques et imprimés, affiches et autocollants), nous avons acquis des ordinateurs avec tous les composants et un système d'exploitation pour les besoins d'entrepôt et de contrôle, de la mémoire pour les serveurs, le programme innovant de modélisation 3D SolidWorks Premium 2020 et le document programme de gestion SolidWorks PDM Professional CAD Editor 2020.

22.11.2020. - après 9 mois de mise en œuvre du projet, nous avons réalisé 11 activités sur un total de 16 activités prévues. Au troisième trimestre, nous avons acquis et mis en œuvre SolidWorks Professional 2020, un programme de modélisation 3D qui comprend une base de données de pièces et d'assemblages d'ingénierie standard. Cette activité comprenait également des tests de programme et la formation des employés dans le cadre du processus de mise à niveau du programme de modélisation 3D, et nous a finalement permis de construire et de concevoir des produits, des outils et des machines de meilleure qualité.

22.02.2021. - après 12 mois de mise en œuvre du projet, nous avons réalisé 13 activités sur un total de 16 activités prévues. Au quatrième trimestre, nous avons acquis et mis en œuvre le sous-système d'information WMS avec code à barres, qui, à l'aide d'appareils intelligents et de lecteurs de codes à barres, automatise la réception, le stockage, la manipulation, la réservation et l'expédition des articles de l'entrepôt, l'inventaire, assure le suivi de la la traçabilité des processus de production, l'analyse des activités réalisées et le reporting.

Nous avons également acquis et mis en œuvre un programme pour l'entrepôt permettant de créer des étiquettes pour le marquage des produits, des matières premières, des consommables, des outils et pièces de rechange et des aciers à outils. En mettant en œuvre ce programme, l'entreprise a permis la transformation numérique de l'ensemble du processus d'étiquetage, de la conception à l'impression des étiquettes. Le résultat de la mise en œuvre est des opérations plus fluides et plus agiles qui permettent à l’entreprise de répondre plus rapidement aux changements des conditions ou des demandes du marché.

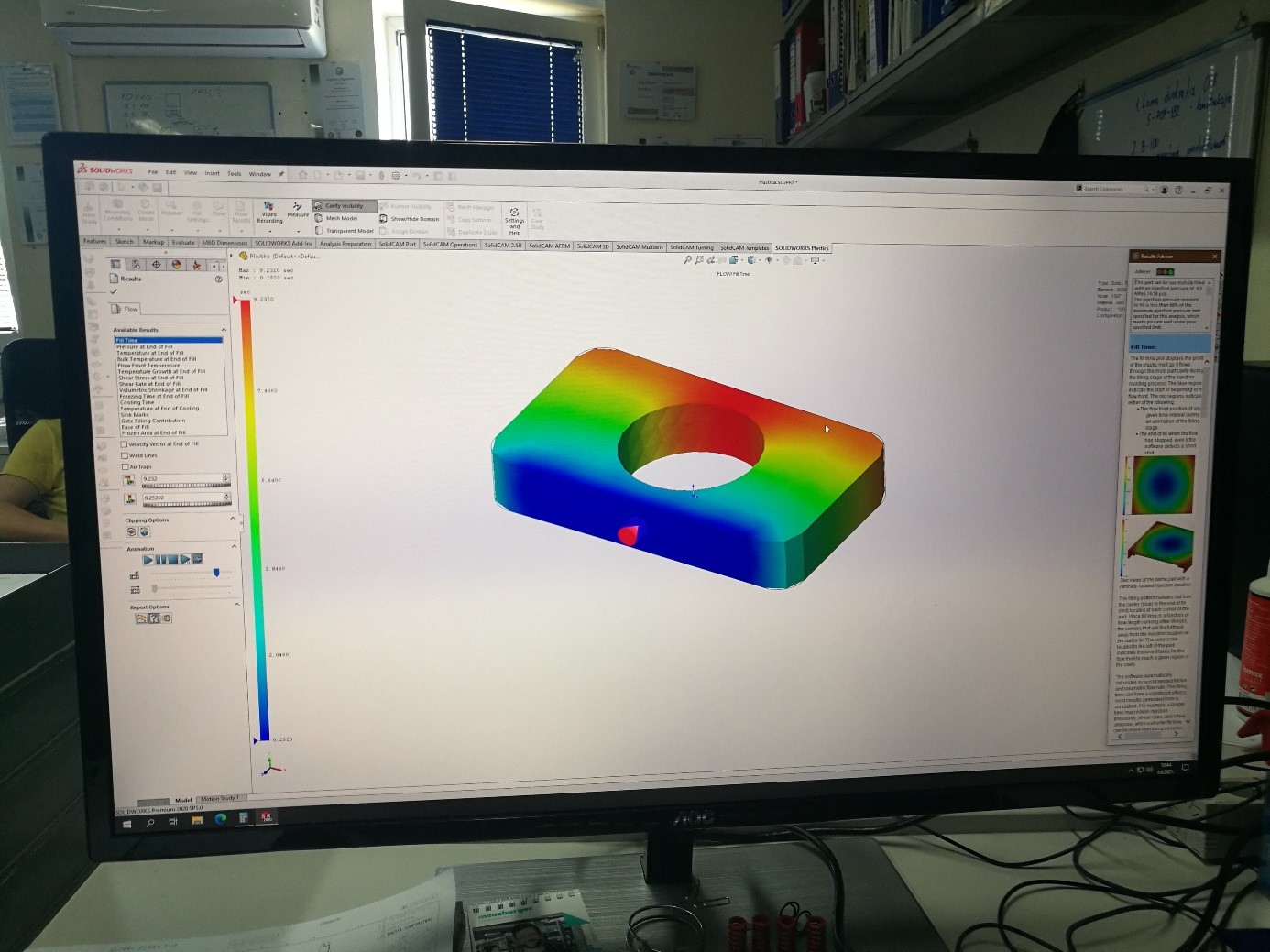

31.05.2021 . - après 15 mois de mise en œuvre du projet, nous avons réalisé les 16 activités sur le total prévu. Au cinquième trimestre, nous avons acquis et mis en œuvre SolidWorks Plastics Professional 2020, le programme de fraisage SolidCAM avec les modules associés et le fil FikusWorks avec post-processeurs.

SolidWorks Plastics Professional 2020 est un programme de développement et de préparation technologique pour la production de produits en plastique basé sur des modèles 3D, version 2020. Le programme est installé sur un ordinateur existant dans le département de construction, il s'agit d'un programme spécialisé pour la construction d'outils pour les produits en plastique.

- Le programme mentionné permet une simulation crédible des paramètres clés lors de la construction et de la conception du moule et du produit lui-même, réduisant ainsi les coûts de développement de produits en plastique.

- Le programme est destiné au développement et à la préparation technologique de la production de produits en plastique basés sur des modèles 3D, avec la technologie du moulage par injection.

Il sert à simuler le processus et accélère le processus de conception des outils de moulage par injection et réduit le nombre de tentatives nécessaires et réduit ainsi le coût de fabrication des outils de moulage par injection.

Le package du programme de fraisage SolidCAM avec les modules associés comprend :

- Fraisage SolidCAM 2,5 D ou équivalent - (2 pcs),

- Module HSM pour traitement haute vitesse ou équivalent - (2 pcs),

- Fraisage de surface à grande vitesse HSS ou équivalent - (2 pièces),

- 3D I - Usinage CNC ou équivalent - (2 pcs),

- Programme de reconnaissance automatique des trous – (2 pcs) i

- Postprocesseur SolidCAM 4x ou équivalent - (1 pc)

La méthode de travail actuelle comprend le traitement manuel des modèles et la création de programmes CNC pour les centres d'usinage programmés. En utilisant le package de programmes mentionné précédemment, les processus de fabrication de pièces d’outils exigeantes, ainsi que de moules pour l’injection plastique, ainsi que de produits et de machines, seraient accélérés. Le progiciel accélère la préparation plus rapide de la technologie de fraisage et la réduction des erreurs, étant donné que le programme est généré directement sur le modèle.

Un programme qui, sur la base d'un modèle 3D, génère assez rapidement du code de programme pour la production sur des machines CNC. Cela contribue à la rapidité et à la fiabilité, puisqu’il n’y a pas de réécriture, mais le code est généré à partir du modèle 3D.

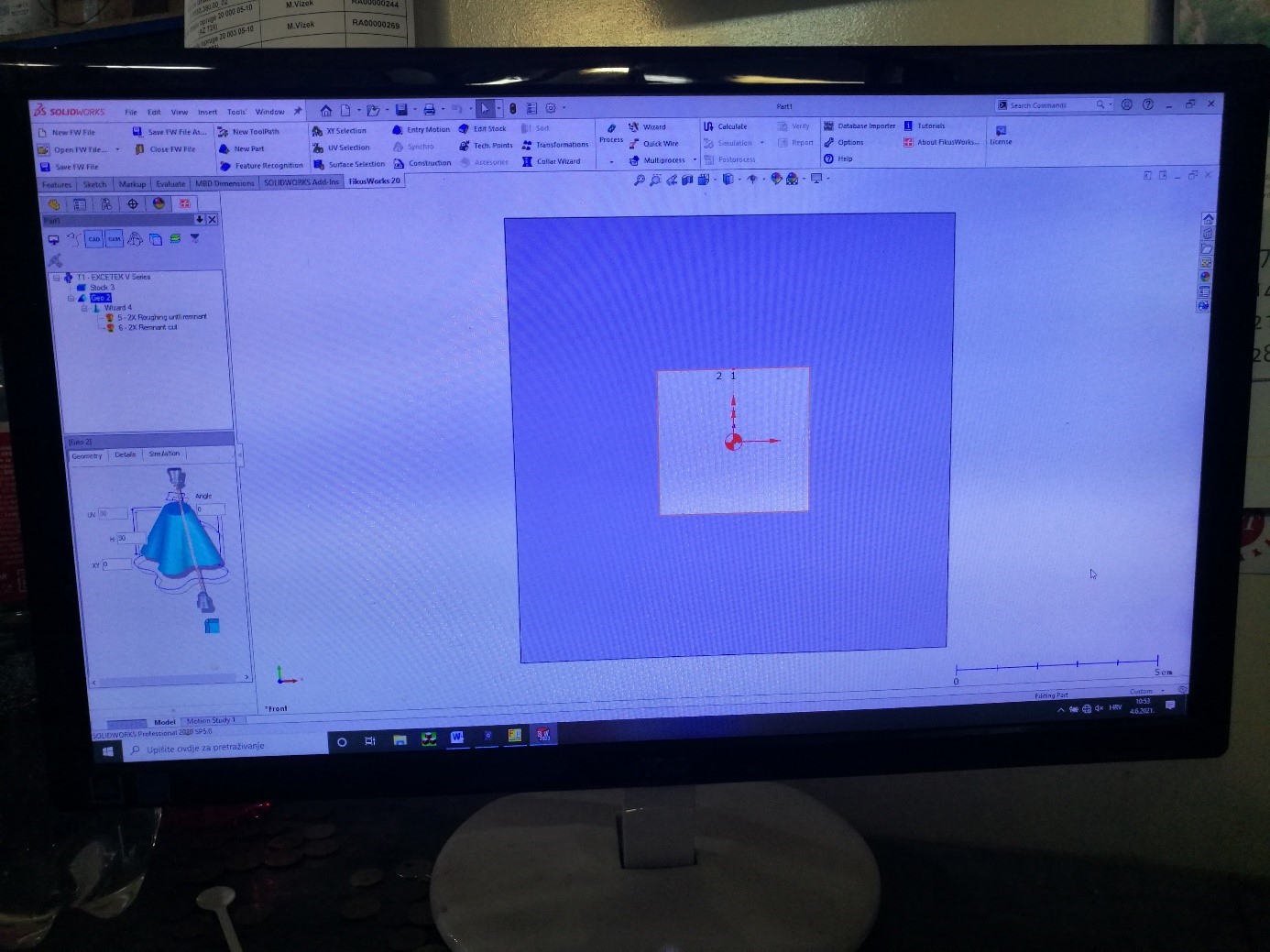

Le fil FikusWorks avec post-processeurs accélère le traitement des dessins et la création du programme lui-même pour erosimat - une machine qui fonctionne sur le principe de l'électroérosion.

- Un post-processeur est une pièce implémentée dans un outil informatique de conception de produits d'ingénierie (CAO ou équivalent), afin d'adapter au mieux le programme CNC à un type spécifique de machine CNC.

- Il accélère le processus de création de programmes CNC et réduit les risques d'erreurs.

20.07.2021. - après 18 mois à compter de la signature du contrat et du début de la mise en œuvre, le 15 juillet 2021. nous avons terminé avec succès la mise en œuvre du projet.

Malgré la crise provoquée par la pandémie du virus covid-19 et toutes ses conséquences négatives sur l'économie (délais de livraison allongés, etc.), nous avons mis en œuvre avec succès toutes les activités prévues dans le projet dans les délais impartis. L'avance reçue au début de la mise en œuvre nous a permis d'avoir un financement stable du projet pour les 18 prochains mois, et sur 965 874,78 HRK de coûts, nous avons reçu 618 516,29 HRK de subventions grâce à 6 demandes de remboursement soumises. Les logiciels et équipements acquis sont opérationnels et des progrès sont déjà visibles dans les processus de construction, de gestion des entrepôts, de comptabilité et d'approvisionnement. On constate également une croissance évidente du nombre d’employés et du chiffre d’affaires total provenant des ventes.

UNION EUROPÉENNE |  Ensemble aux fonds européens |

Le projet a été cofinancé par l'Union européenne à partir du Fonds européen de développement régional.

Personne de contact pour plus d’informations : Nenad Mrzlečki

Liens vers les pages pertinentes : www.strukturnifondovi.hr